cGMP – Voice of the Customer

An interview with an industry expert in the manufacture of cGMP medicinal products.

We interviewed an industry expert in the manufacture of cGMP medicinal products to understand what they would expect from a third party company before they would consider storing their material with them.

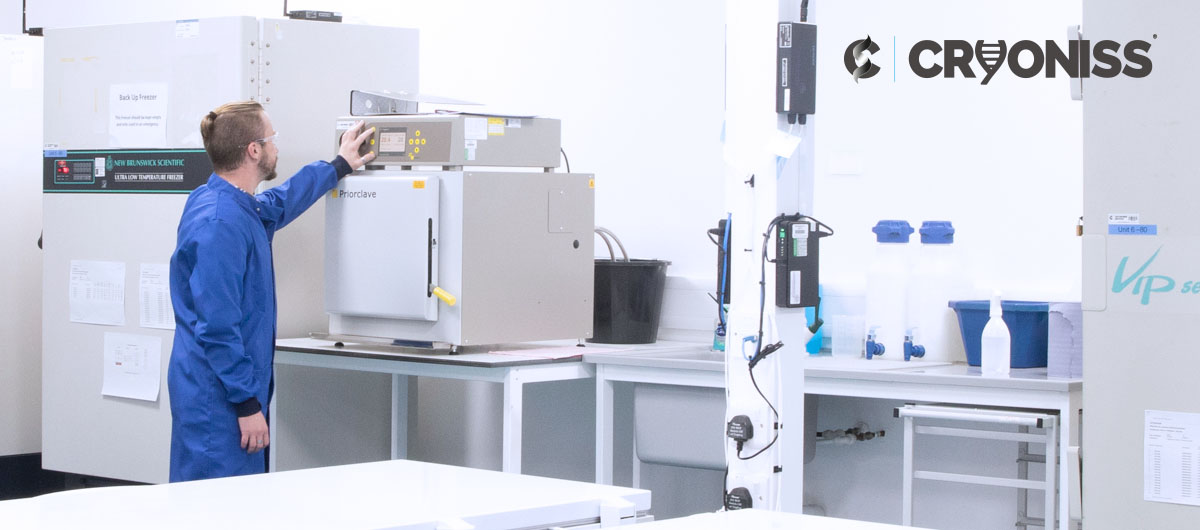

Cryoniss procedures and processes have been developed to ensure sample and product integrity is of the highest priority, alongside our customer service.

Cryoniss are a contract service organisation, which offers third parties’ temperature-controlled storage and logistics management services for biological samples and / or medicinal products or manufactured products or chemical compounds.

Cryoniss works to the principles of Good Laboratory Practice (GLP), Good Clinical Practice (GLP), Good Clinical Laboratory Practice (GCLP) and current Good Manufacturing Practice (cGMP).

Samples are regulated by the Health and Safety Executive, Animal Plant and Health Agency and the Human Tissue Authority.

Alongside these Cryoniss adheres to regulations pertaining to The Medicines for Human Use (Clinical Trials) Regulations 2004 and European Medicines Agency reflection paper for laboratories carrying out clinical analysis.

To enable handling of medicinal products, Cryoniss complies with the EC guidelines for GDP of Medicinal Products for Human Use, Directive 2001/83/EC Community Code relating to Medicinal Products for Human Use and Regulations 43-45 of the Human Medicines Regulations 2012.

Good Manufacturing practice (GMP)

GMP is the minimum standard that a medicines manufacturer must meet in their production processes. Products must be of consistent high quality, be appropriate to their intended use and meet the requirements of the marketing authorisation (MA) or product specification. Eudralex Volume 4 Good Manufacturing Practice is followed.

We interviewed an industry expert in the manufacture of cGMP medicinal products to understand what they would expect from a third party company before they would consider storing their material with them:

What are the main considerations when choosing off-site GMP storage solutions?

- Must have correct credentials to store GMP material

- Must have a temperature-controlled Facility Management System with multiple system alert notifications

- Must have a traceable catalogued system for product management in the form of a LIMS or SAP system

- Must have good turnaround of sample requests

- Ideally logistics would be provided by the storage company

How can Cryoniss support these considerations?

- We have been audited by the MHRA and are licensed to store GMP materials. We work to cGMP standards. We have ISO9001 certification.

- Our Laboratory Monitoring System is 21 CFR part 11 compliant and has alert notifications that are sent to all designated and trained individuals via text and email.

- Our laboratory inventory management system is HIPAA compliant, secure, fully auditable and cloud-based.

- We have standard next day sample release. If samples are requested by 11am the previous working day.

- We provide complete end-to-end logistics support via a network of experienced couriers who we hold the same high standards as ourselves for product integrity. Our service includes navigating customs and documentation required for international shipping.

What if the needs of a product are complex or unique how can Cryoniss accommodate this?

We carry out rigorous Customer Onboarding, in which all new projects are triaged and as appropriate and checks and balances implemented to ensure ongoing compliance against the relevant regulations. For cGMP relevant material, bespoke quality control checks can be implemented and agreed in quality agreements or tailored product manuals. These procedures are created in collaboration with the customer and signed off by both parties to ensure satisfaction with processes and procedures.

For example: If the customer requires cGMP material to be segregated from other material for any reason, the level of required segregation must be determined during onboarding and this will then be written into the quality agreement /product manual / new SOPs as appropriate.

What sets you apart from other storage providers in your ability to store GMP products?

The Cryoniss team is made up of ex-scientists who understand the importance of sample integrity to the outcomes of experimental success. We have specific team members who have direct experience of working in companies that have produced GMP products, therefore the fundamental behaviours required to work to this stringent level of compliance are embedded within the foundations of our ways of working.

Our mission is to enable our customers to carry out exceptional science and we achieve this by:

- Providing high quality end-to-end sample, medicinal product or manufactured product logistics management services with our preferred partners, who have the same values pertaining to customer focus and sample integrity as we do.

- Providing high quality storage and sample/product handling solutions, employing the latest technologies and process improvements. Providing access to the latest scientific data and best practice guidance to ensure our customers are optimising their results by using high quality reagents/samples or products.

- Supporting our customers with regulatory requirements to ensure they are compliant and also reduce the time they spend on navigating governmental websites.

- Support companies to access high quality patient material from ethical biobanks.

- Support customers with provision of highly qualified cell banks via outsourced tissue culture and quality control testing services.

By achieving these objectives, our customers will be working with high quality reagents which are the keystone of any good experiment, and with our support with regulatory and logistics management tasks, they have more time to focus on developing their business.

Equally, Cryoniss supports researchers and pharmaceutical companies with GDP compliant storage and logistics management of medicinal products, including investigational medicinal products (IMP) for clinical trials.

Cryoniss works to the applicable principles of Good Laboratory Practice (GLP), Good Clinical Practice (GCP), Good Clinical Laboratory Practice (GCLP) and Good Manufacturing Practice (GMP).

Samples are regulated by the Health and Safety Executive, Animal Plant and Health Agency and the Human Tissue Authority. Alongside these, Cryoniss adheres to regulations pertaining to The Medicines for Human Use (Clinical Trials) Regulations 2004 and European Medicines Agency reflection paper for laboratories carrying out clinical analysis.

Cryoniss is compliant with Good Distribution Practice (GDP) and holds a WDA(H) licence. To enable handling of medicinal products, Cryoniss complies with the EC guidelines for GDP of Medicinal Products for Human Use, Directive 2001/83/EC Community Code relating to Medicinal Products for Human Use and Regulations 43-45 of the Human Medicines Regulations 2012.

To enable handling of chemical compounds, Cryoniss complies with COSHH Regulations.

Want to find out more ?

To talk to us about our services and how they can best benefit your business, please get in touch